When you think about global trade, large ships carrying containers often come to mind. But not all cargo travels in boxes. Millions of tons of raw materials like coal, grain, and iron ore move across oceans every day. These shipments depend on a special type of ship called a “bulk carrier.”

At first glance, bulk carrier ships seem simple on the surface. But their design and operation are far from basic. Every year, they carry enough materials to support industries, build cities, and fuel economies around the world.

Unlike container ships or tankers, bulk carriers handle unpackaged cargo. This fact changes everything about how they are built, loaded, and operated. If you want to understand how raw materials reach factories, power plants, and farms globally, you need to know about bulk carrier ships.

In this article, we’ll explore what makes these ships unique, their types, the cargo they carry, how they operate, and the safety challenges they face.

Types of Bulk Carrier Vessels

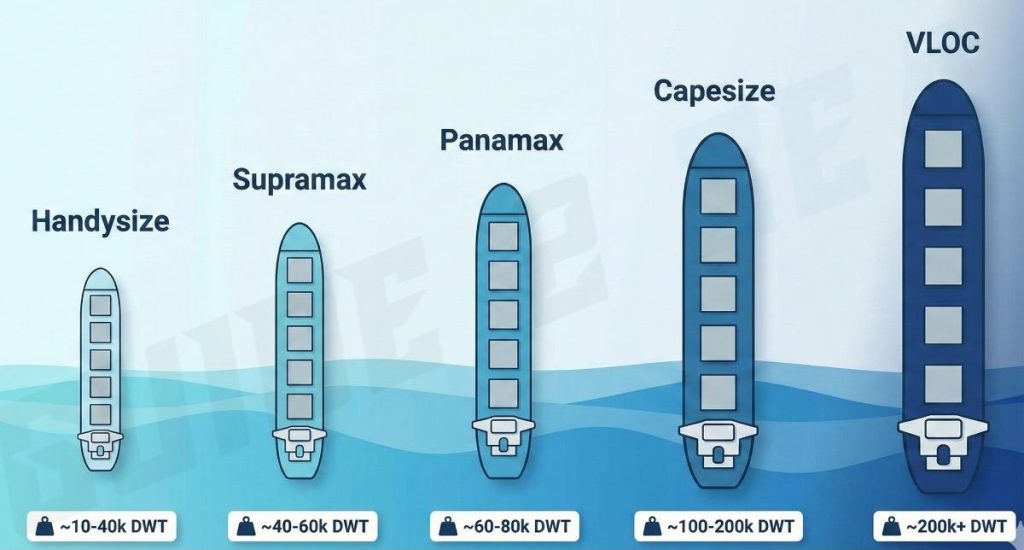

Bulk carriers come in many sizes and types. Each built for specific cargo and trading routes. Knowing these types helps you understand why shipping is so complex.

1. Handysize

Handysize bulk carriers are small but flexible. They usually measure between 15,000 and 35,000 deadweight tons (DWT). These ships can access smaller ports, navigate narrow channels, and serve regional routes efficiently. Despite their smaller size, Handysize ships play a critical role in connecting remote ports to global markets.

2. Handymax / Supramax

Handymax and Supramax ships are slightly larger. These ships carry between 40,000 and 60,000 DWT. They have more cargo space and often include cranes on board. This means they can load and unload cargo in ports without shore equipment. This makes them highly flexible, especially in developing regions or ports with limited infrastructure.

3. Panamax

Panamax bulk carriers are built to pass through the Panama Canal. Their size ranges from 65,000 to 80,000 DWT. They dominate major long-distance trade routes.

4. Capesize

Capesize vessels are enormous, usually above 150,000 DWT. They are too big for the Panama or Suez Canal. Because of this matter, these ships take the routes around continents like Africa or South America. Capesize ships are designed for extremely heavy cargo, like iron ore and coal. These ships are crucial to supplying industrial hubs worldwide.

5. Very Large Ore Carriers (VLOCs)

VLOCs are the giants of the ocean. They can carry more than 200,000 DWT. These ships transport huge volumes of iron ore and coal for large-scale industrial operations. They are engineered for efficiency, strength, and stability on long voyages across rough oceans.

Transitioning between these types depends on port access, cargo type, and trade routes. Shipping companies carefully choose the right vessel to balance cost, efficiency, and accessibility.

How Bulk Carriers Are Designed

Although they look simple, bulk carriers are highly engineered machines. Their design balances efficiency, safety, and cargo capacity.

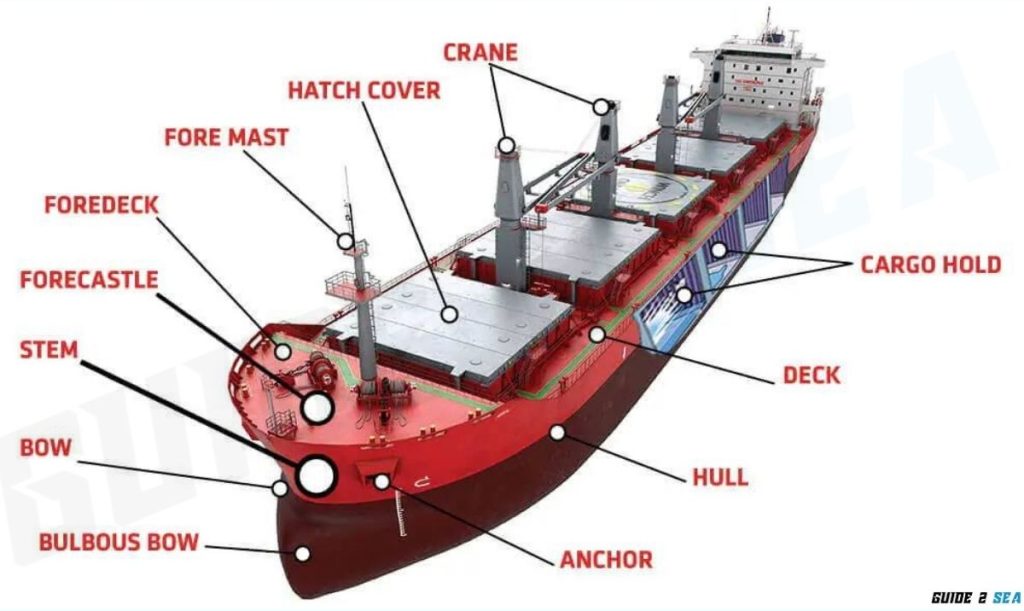

- Cargo Holds:

Cargo holds are the large, empty spaces designed to store dry cargo safely. The number and size of holds depend on the ship type and intended cargo. Modern bulk carriers often have multiple holds separated by strong bulkheads.

- Hatches:

Hatches are the openings on the deck for loading and unloading cargo. They need to be strong and watertight to prevent accidents and cargo loss. Many ships have hydraulic or electrically operated hatch covers to make operations faster.

- Hull Design:

A bulk carrier’s hull is long, wide, and flat-bottomed to handle heavy loads. The hull shape affects stability, speed, and fuel efficiency. Naval architects design hulls carefully to prevent cargo from shifting and ensure the ship sails smoothly, even in rough seas.

- Onboard Cranes:

Some bulk carriers have cranes for self-loading and unloading. This feature allows them to operate in ports that lack heavy equipment. Supramax and Handymax ships often have this advantage.

- Ballast Tanks:

Ballast tanks maintain stability. When a ship sails partially empty, water fills these tanks to balance the vessel. Ballast management is critical to prevent listing, capsizing, or structural stress.

Designing a bulk carrier requires balancing cargo capacity, stability, safety, and operational efficiency. Even small design flaws can create risks at sea.

Read: What is Ballast Water in Shipping?

Final thought

Bulk carriers play an important role in global trade. They transport the raw materials that power industries, build cities, and feed nations. While they may appear simple, their design, operation, and safety management are highly complex.

From small Handysize vessels to massive Capesize giants, each ship type has a purpose and a trade route it serves best. The cargo they carry ranges from coal and grain to iron ore and fertilizers, and each comes with its own handling challenges.

Despite the risks, skilled crews, careful design, and modern technology ensure that bulk carriers continue to deliver essential goods worldwide. These ships may not always grab headlines like container ships or luxury liners, but they are the silent workhorses that keep the world moving.

Understanding bulk carriers gives you a glimpse into the scale, complexity, and importance of maritime trade.